The Heart of the Machine: What is a Pressure Washer Pump?

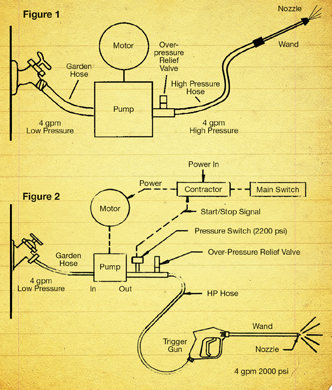

A pressure washer pump is the core component of a pressure washer, responsible for generating high-pressure water flow that enables efficient cleaning. Understanding how a pressure washer pump works is essential for optimal performance and maintenance. The pump plays a crucial role in the overall system, converting the energy from the engine or motor into hydraulic energy, which is then used to propel water through the nozzle. This process creates a high-pressure stream of water that can effectively remove dirt, grime, and other substances from surfaces.

The pressure washer pump is designed to withstand the rigors of high-pressure operation, with components such as the inlet, outlet, valves, and pistons working together to create a seamless flow of water. The pump’s function is to increase the pressure of the water, typically from a low-pressure source such as a garden hose, to a high-pressure output that can reach levels of up to 4,000 pounds per square inch (PSI). This high-pressure water flow is what makes pressure washers so effective at cleaning a variety of surfaces, from driveways and sidewalks to buildings and equipment.

Pressure washer pumps are available in various types, including axial, centrifugal, and triplex pumps, each with its own unique characteristics and advantages. Axial pumps, for example, are known for their high flow rates and are often used in heavy-duty applications, while centrifugal pumps are more compact and energy-efficient. Triplex pumps, on the other hand, are designed for high-pressure applications and are commonly used in industrial settings.

Regardless of the type of pump, understanding how a pressure washer pump works is critical for proper maintenance and troubleshooting. Regular maintenance, such as cleaning and lubricating the pump, can help extend its lifespan and ensure optimal performance. Additionally, being able to identify and troubleshoot common issues, such as leaks or clogs, can help minimize downtime and keep the pressure washer running efficiently.

How Does a Pressure Washer Pump Work: A Step-by-Step Explanation

Understanding how a pressure washer pump works is crucial for optimal performance and maintenance. The process involves several key steps that work together to generate high-pressure water flow. Here’s a step-by-step explanation of how a pressure washer pump works:

Step 1: Water Intake – The pump draws in water from a low-pressure source, such as a garden hose, through the inlet. The inlet is typically connected to a filter or strainer to prevent debris from entering the pump.

Step 2: Pressurization – The water is then pressurized by the pump’s pistons or valves, which create a high-pressure zone within the pump. This high-pressure zone is what drives the water out of the pump and through the nozzle.

Step 3: Compression – As the pistons or valves move, they compress the water, increasing its pressure and flow rate. This compression is what creates the high-pressure water flow that is characteristic of pressure washers.

Step 4: Delivery – The high-pressure water flow is then delivered to the nozzle, where it is accelerated to high velocity, creating a powerful cleaning stream. The nozzle is typically designed to focus the water stream, increasing its cleaning power and efficiency.

Step 5: Exhaust – After the water has been delivered to the nozzle, the pump’s exhaust valve opens, allowing the high-pressure water to exit the pump and flow back into the tank or drain. This process is repeated continuously, creating a steady flow of high-pressure water.

By understanding how a pressure washer pump works, users can better maintain and troubleshoot their equipment, ensuring optimal performance and extending the lifespan of the pump. Regular maintenance, such as cleaning and lubricating the pump, can help prevent common issues and keep the pressure washer running efficiently.

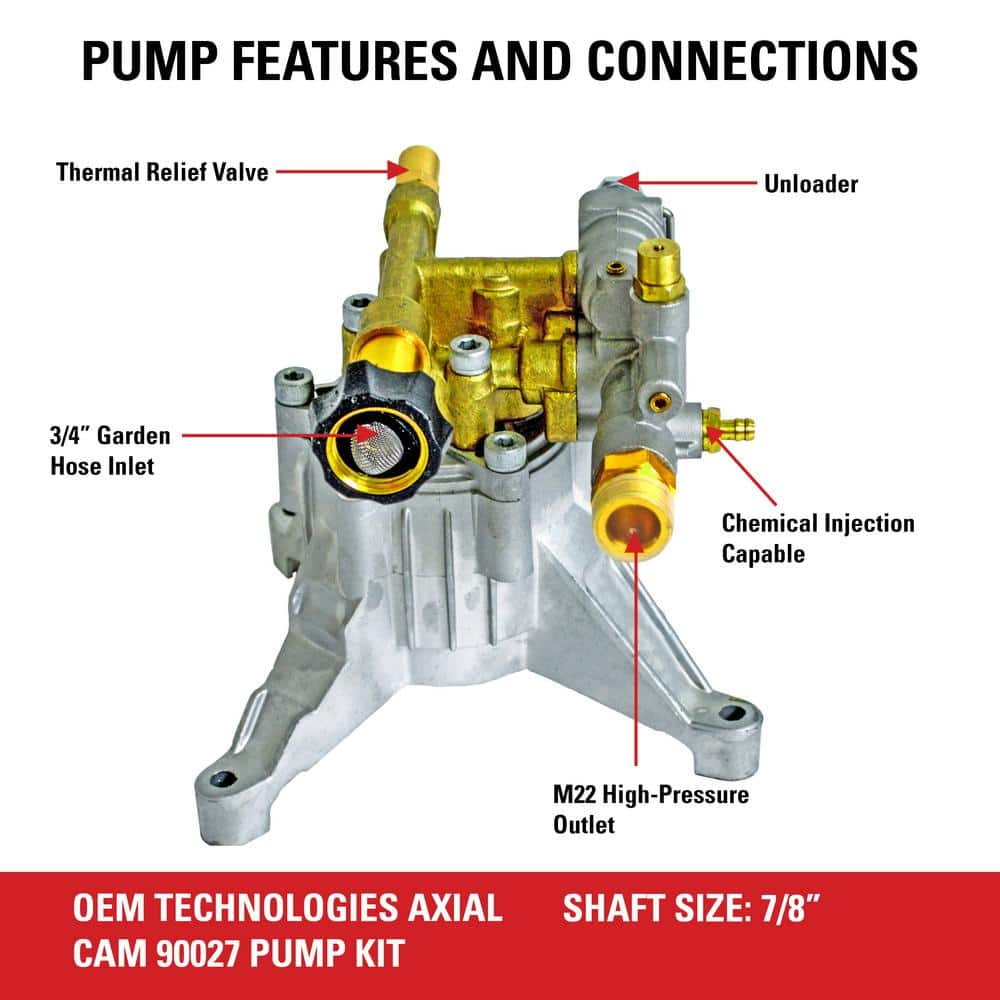

The Key Components of a Pressure Washer Pump: A Closer Look

A pressure washer pump is composed of several key components that work together to generate high-pressure water flow. Understanding the function of each component is essential for proper maintenance and troubleshooting. Here’s a closer look at the main components of a pressure washer pump:

Inlet: The inlet is the component that draws in water from a low-pressure source, such as a garden hose. It’s typically connected to a filter or strainer to prevent debris from entering the pump.

Outlet: The outlet is the component that delivers the high-pressure water flow to the nozzle. It’s typically designed to withstand high pressure and flow rates.

Valves: The valves are responsible for controlling the flow of water into and out of the pump. They’re typically designed to open and close in a specific sequence to create the high-pressure water flow.

Pistons: The pistons are the components that create the high-pressure water flow by compressing the water. They’re typically made of durable materials, such as stainless steel or ceramic, to withstand the high pressure and flow rates.

Seals and Gaskets: The seals and gaskets are responsible for preventing leaks and maintaining the high pressure within the pump. They’re typically made of durable materials, such as rubber or Teflon, to withstand the high pressure and flow rates.

By understanding the function of each component, users can better maintain and troubleshoot their pressure washer pump, ensuring optimal performance and extending the lifespan of the pump. Regular maintenance, such as cleaning and lubricating the pump, can help prevent common issues and keep the pressure washer running efficiently.

Additionally, understanding the key components of a pressure washer pump can help users choose the right pump for their specific needs. For example, users who need high-pressure water flow for heavy-duty cleaning tasks may require a pump with a higher horsepower rating or a more durable piston design.

Types of Pressure Washer Pumps: Which One is Right for You?

When it comes to choosing a pressure washer pump, there are several types to consider, each with its own unique characteristics and advantages. Understanding the different types of pressure washer pumps can help you select the right one for your specific needs. Here are some of the most common types of pressure washer pumps:

Axial Pumps: Axial pumps are one of the most common types of pressure washer pumps. They are known for their high flow rates and are often used in heavy-duty applications. Axial pumps are typically more affordable than other types of pumps, but they can be more prone to wear and tear.

Centrifugal Pumps: Centrifugal pumps are another popular type of pressure washer pump. They are known for their high pressure and flow rates, making them ideal for heavy-duty cleaning tasks. Centrifugal pumps are typically more expensive than axial pumps, but they are also more durable and require less maintenance.

Triplex Pumps: Triplex pumps are a type of pressure washer pump that uses three pistons to create high pressure and flow rates. They are known for their high efficiency and are often used in industrial and commercial applications. Triplex pumps are typically more expensive than axial and centrifugal pumps, but they offer superior performance and durability.

When selecting a pressure washer pump, it’s essential to consider your specific cleaning needs. If you need a pump for light-duty cleaning tasks, an axial pump may be sufficient. However, if you need a pump for heavy-duty cleaning tasks, a centrifugal or triplex pump may be more suitable.

In addition to the type of pump, it’s also essential to consider other factors such as pressure, flow rate, and horsepower. Understanding how a pressure washer pump works and how to properly maintain and use it can help you get the most out of your pump and ensure optimal performance.

Tips for Maintaining and Troubleshooting Your Pressure Washer Pump

Regular maintenance and troubleshooting are essential to ensure the optimal performance and longevity of your pressure washer pump. Here are some tips to help you maintain and troubleshoot your pressure washer pump:

Cleaning: Regular cleaning is essential to prevent debris and dirt from accumulating in the pump and causing damage. Use a soft-bristled brush to clean the pump’s exterior and interior, and make sure to flush the pump with clean water after each use.

Lubricating: Lubricating the pump’s moving parts is essential to prevent wear and tear. Use a high-quality lubricant specifically designed for pressure washer pumps, and apply it according to the manufacturer’s instructions.

Replacing Worn-Out Parts: Regularly inspect the pump’s components for signs of wear and tear, and replace them as needed. This includes the seals, gaskets, and pistons.

Troubleshooting: If you experience any issues with your pressure washer pump, such as low pressure or leaks, troubleshoot the problem by checking the pump’s components and connections. Consult the manufacturer’s instructions or contact a professional if you’re unsure.

Common Issues: Some common issues that may arise with pressure washer pumps include low pressure, leaks, and overheating. To prevent these issues, make sure to regularly maintain the pump and troubleshoot any problems promptly.

By following these tips, you can ensure the optimal performance and longevity of your pressure washer pump. Remember to always refer to the manufacturer’s instructions for specific maintenance and troubleshooting recommendations.

How to Choose the Right Pressure Washer Pump for Your Cleaning Needs

Choosing the right pressure washer pump for your cleaning needs can be a daunting task, especially with the numerous options available in the market. However, by considering a few key factors, you can select the perfect pump for your specific cleaning tasks.

Pressure: The first factor to consider is the pressure required for your cleaning tasks. Different cleaning tasks require different levels of pressure, so it’s essential to choose a pump that can deliver the required pressure. For example, if you need to clean a large area with heavy dirt and grime, you may require a pump with higher pressure.

Flow Rate: The flow rate of a pressure washer pump refers to the amount of water it can deliver per minute. A higher flow rate means more water is delivered, which can be beneficial for larger cleaning tasks. However, it also means more water is consumed, which can increase costs.

Horsepower: The horsepower of a pressure washer pump refers to its power output. A higher horsepower means more power is delivered, which can be beneficial for tougher cleaning tasks. However, it also means more energy is consumed, which can increase costs.

Other Factors: In addition to pressure, flow rate, and horsepower, there are other factors to consider when choosing a pressure washer pump. These include the type of pump, the material of the pump, and the warranty offered by the manufacturer.

By considering these factors, you can choose the right pressure washer pump for your specific cleaning needs. Remember to always refer to the manufacturer’s instructions for specific guidance on selecting the right pump.

It’s also important to note that understanding how a pressure washer pump works can help you make an informed decision when choosing a pump. By knowing how the pump works, you can better understand its capabilities and limitations, which can help you choose the right pump for your needs.

Real-World Applications of Pressure Washer Pumps: Case Studies and Examples

Pressure washer pumps are used in a variety of industries and applications, including construction, agriculture, and cleaning services. Here are some real-world examples of pressure washer pumps in action:

Construction: Pressure washer pumps are commonly used in the construction industry to clean equipment, buildings, and surfaces. For example, a construction company may use a pressure washer pump to clean a concrete mixer or a bulldozer.

Agriculture: Pressure washer pumps are also used in the agriculture industry to clean equipment and surfaces. For example, a farmer may use a pressure washer pump to clean a tractor or a barn.

Cleaning Services: Pressure washer pumps are used in the cleaning services industry to clean buildings, sidewalks, and other surfaces. For example, a cleaning service company may use a pressure washer pump to clean a parking garage or a sidewalk.

Other Industries: Pressure washer pumps are also used in other industries, such as manufacturing, mining, and oil and gas. For example, a manufacturing company may use a pressure washer pump to clean equipment or surfaces, while a mining company may use a pressure washer pump to clean mining equipment.

Case Studies: Here are some case studies of pressure washer pumps in action:

Case Study 1: A construction company used a pressure washer pump to clean a concrete mixer. The pump was able to remove dirt and grime from the mixer, allowing it to be used again.

Case Study 2: A farmer used a pressure washer pump to clean a tractor. The pump was able to remove dirt and grime from the tractor, allowing it to be used again.

Case Study 3: A cleaning service company used a pressure washer pump to clean a parking garage. The pump was able to remove dirt and grime from the garage, allowing it to be used again.

These case studies demonstrate the effectiveness of pressure washer pumps in a variety of industries and applications. By understanding how a pressure washer pump works and how to properly maintain and use it, you can unlock its full potential and achieve optimal performance.

Conclusion: Mastering the Power of Pressure Washer Pumps

In conclusion, understanding how a pressure washer pump works is crucial for optimal performance and maintenance. By knowing the key components, types, and applications of pressure washer pumps, you can unlock their full potential and achieve optimal performance.

Remember, a pressure washer pump is the heart of the machine, and its proper functioning is essential for effective cleaning. By following the tips and guidelines outlined in this article, you can ensure that your pressure washer pump is working at its best.

Whether you’re a professional contractor or a homeowner, understanding how a pressure washer pump works can help you get the most out of your equipment. By mastering the power of pressure washer pumps, you can achieve cleaner surfaces, increased efficiency, and reduced maintenance costs.

In summary, the key takeaways from this article are:

Understanding the key components of a pressure washer pump, including the inlet, outlet, valves, and pistons.

Knowing the different types of pressure washer pumps, including axial, centrifugal, and triplex pumps.

Understanding the applications of pressure washer pumps in various industries, including construction, agriculture, and cleaning services.

Following the tips and guidelines for maintaining and troubleshooting pressure washer pumps.

By mastering the power of pressure washer pumps, you can unlock their full potential and achieve optimal performance.